CAUSE OF FAILURE OF RUBBER PRODUCTS - TYRE &

NON-TYRE

Dr. S. N. Chakravarty

President

Elastomer Technology Development Society

812 Devika Tower , 6 Nehru Place

New Delhi 110019

Rubber products, both Tyre & Non-Tyre goods, are

used in indoor and outdoor application under various conditions. Some are

expected to withstand atmospheric conditions (Oxygen, Ozone, Sunlight &

UV), others under dynamic condition (flex fatigue, typical example is Tyre

While developing & manufacturing a rubber product

all these factors are kept in mind while formulating the compound & curing

of the products.

Let us see what are different factors which could be

the cause of failure of rubber products during usage.

1. Application

/ Service related factors

To develop a rubber product most important

information required are its application / usage pattern.

To find out whether the product is

a) subjected to weather conditions Oxygen / Ozone / UV / Sun

Light / UV etc.

b) Temperature of usage

e) Dynamic

application (Flex Fatigue)

d) Abrasion

/ Wear condition

e)

Contact with Oil & Solvents, Chemicals, Acid & Alkali etc.

Lecture delivered at Kolkata , Chennai, Ludhiana, Delhi, India

2. Specification

To develop a product to meet application requirement,

basic specification given is followed. It is supposed to give all requirement

of properties (e.g. TS, M, SH, Sp. Gr., Abrasion, Flex, Ozone & Oil

resistance etc) & retention of these properties over the usage period,

judged by carrying out ageing at an elevated temperature.

3.

Material – Polymer / Elastomer &

Ingredients.

Depending on requirement from the Product during

usage base Polymer / Elastomer

in chosen. For example

a) For normal applications, temperature limited to

70º / 80ºC and no Ozone & Oil resistance etc requirement, NR / SBR / BR

rubbers may satisfy.

b) In case of higher temperature limit for usage –

one has to go for CR, NBR, CPE, EPDM, HNBR, Silicone & ultimately FKM type

of rubbers.

c) In case of product coming in contact with Fats

& Oils, Solvent etc. choice may be NBR, HNBR, Arcylate & FKM depending

on application combination.

d) For Ozone resistance the choice would be CR, CPE,

EPDM, Silicone, FKM depending on severity of application.

e) In case of high temperature & Oil / Solvent

contact as well as Ozone resistance requirement, choice is limited to FKM.

f) For both high & very low temperature

application Silicone rubber may be the choice.

g) For electrical insulation & resistance

property requirement, ECO may be preferred.

h) Retention of gas / air ( impermeability) property

is met by Butyl / Halo butyl rubber.

( Automotive inner tube & inner liner application).

i) For high chemical resistance choice are CSM, FKM

etc.

Wrong choice of base polymer for specific application

often is the vital cause of product failure.

4. Compounding

Compounding formulation play important role in a

product’s performance & life expectancy. Vital are the reinforcement of the

product to achieve desired level of physical properties (fillers like Carbon

Black gives best protection against deterioration, also Silica / Siliane

Coupling agent system provides high ageing resistance) and curing system ( S

& Accelerators / Activator choice & phr level in case of diene rubber

or other curing agents for special Synthetic Rubber).

E

.V .System

Efficient vulcanizing (EV) systems are defined as

those in which no sulphur or sulphur donor is used for crosslinking purposes.

Such vulcanizates are normally associated with a high proportion of

monosulphidic and dissulphidic crosslinks in the network. EV system gives

vulcanizate with exceptionally good resistance both to reversion and to heat

ageing. They are of particular interest for

-Manufacture of thick articles to avoid uneven cure

(e.g. in injection moulding)

- Resistance to heat ageing required

beyond the capability of antioxidants.

- Alternative to expensive

non-discolouring antioxidants.

Both high accelerator / low

sulphur system and the sulphur donor system give good processing safety and

excellent resistance to reversion and to ageing.

Semi-Ev System ( Partial replacement of Sulphur )

Good retention of vulcanizate properties during

ageing. With mainly monosulphidic or disulphidic crosslinks these are more resistant to oxidative and thermal

degradation than conventional

vulcanizates which have a high proportion of polysulphidic cross-links.

The efficient systems have low initial fatigue life, but are very stable and

show no significant change on ageing.

Sulphur-

Free Vulcanization System for Diene Rubber

Vulcanization

with Sulphur Compounds without Free Sulphur

Crosslininking mechanism which, though not dependent

on additions of sulphur nevertheless form effective crosslink sites containing

sulphur atoms.

Vulcanization

with Sulphur Donors

These choice & dosage level have bearing on physico

– mechanical properties (SH / TS / M / Tear, Abrasion loss / Wear

Characteristics, ageing at a higher temperature, flex fatigue etc.

Anti-degredants

Choice & dosage level of anti-degredants

(antioxidants / antiozonants, M.C. Wax) play important role in product life

& performance, Aminic type of anti-degredants are more effective against

heat ageing where as p-plylenediamine

types are effective against ozone & flex fatigue resistance. In case of

non-black products bisphenolic & MBI type are used to a level of success.

On ageing, rubber vulcanizate (product), degrades and

physical properties drop, ultimately to a point that the product fails. Ageing

is primarily oxidative (ozone) degradation; heat/ sunlight/ UV /Copper/ Iron / flexing

all have catalytic effect on degradation. Oxidative ageing breaks down the rubber chain unsaturation point) causing

drop in physical properties. Hence, while compounding, one has to protect the product

against oxidative and other ageing factors.

Following is the reaction mechanism for the

auto-oxidation of pure hydrocarbons in the absence of added initiators or

inhibitors.

The oxidation of a rubber molecule is shown below.

The oxidation of a rubber molecule is shown below.

NR & SR are attacked by oxygen even at room

temperature and the reaction is accelerated by heat, light and the presence of

certain metallic impurities which catalyse the decomposition of the peroxides

to form free radicals. Consequently, the addition of an antioxidant is required

to minimize oxidative degradation. All hydrocarbon polymers undergo scission as

a consequence of thermal oxidation.

5.

Processing – Dispersion of ingredients

& Machinery.

Processing steps – Mixing, Extrusion, Calendaring,

etc. contribute towards incorporation / distribution & dispersion of large

quantity of fillers – both reinforcing & non-reinforcing in a compound,

Dispersion of ingredients is important to achieve desired property level and

product performance or premature failure. Improper dispersion of ingredients and

presence of grits in a product subjected to flexing will fail prematurely because the stress factor on

those points will be different causing failure. Abrasion / wear is also

affected.

Curing system and curing process perhaps the most important

criteria in a product’s property level and performance.

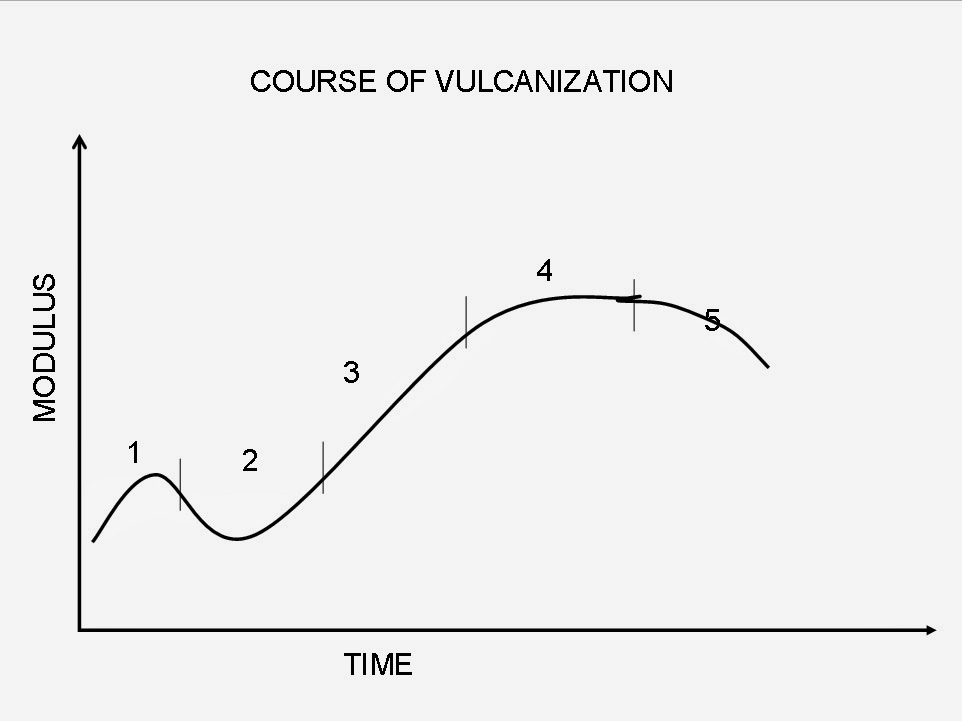

Stages of vulcanization : is followed by checking of physical property like

modulus or shear modulus with time of cure.

Five distinct stages are observed.

1. Incubation Period

2. Induction stage ( Scorch )

3. Crosslinking stage

4. Plateau

Incubation period

During this period , the rubber compound is heated to

the curing temperature . Rubber is a bad conductor of heat. For thin walled

goods, the incubation period is short but in case of thick-walled rubber goods,

the interior of the article may take a fairly long time to get heated to the

curing temperature.

Induction stage

The time interval at the curing temperature at which

no measurable crosslinking can be observed is know as the induction

period. This period depends on the

polymer and the curing system used.

The induction period represents the safety margin in

processing the stock and is an indication of the storage life of the stock.

Every compound must have a sufficient induction

period so that the compound processes satisfactorily.

Crosslinking

or Vulcanization

This

is the period when crosslinking starts, the rate depending on the cure system,

the compound and the temperature of cure.

Plateau

This is the period during which the physical

property, after attaining the maximum value, remains constant with continued

cure.

Reversion

This occurs in the vulcanization of natural rubber ,

polyisoprene and butyl rubbers. On prolonged cures, the physical properties of

the vulcanizate will start deteriorating. Other synthetic rubbers like SBR,

NBR, CR will not generally show reversion.

These five stages are exhibited when sulfur is used

as the cross linking agent. When the cure systems other than elemental sulfur

are used the reversion stage is generally absent. With sulfur the reversion

occurs because of the fact that poysulfidic crosslinkages formed at the earlier

stages are rather unstable and break up on continued heating.

Physical property level and product performance is

based on the crosslink density and nature / type of crosslink formed by

vulcanization.

Higher Sulphur level in the compound produces more

polysulphidic cross links which gives

higher TS / M as well flex fatigue but has lower resistance to heat (oxidative) aging by which polysulphidic

crosslink’s breaks down to

lower sulphidic crosslink and properties fall.

Lower sulphur & higher accelerators (specially

sulphenamide types) produces more stable crosslink’s and sulphurless curing

gives most stable structure which

have very good resistance to heat ageing & retains

the property level for longer period of product life.

Similarly cure temperature & time also have

bearing on vulcanizate structure and

in turn on ageing effect.

7.

Product Design - Geometry /

Construction / Safety factor.

It has been shown that the design of the product has

pronounced effect on certain

application behaviour life flex fatigue, wear characteristics, compression set

etc. Higher the displacement from the “null” point during flexing of a product

(e,g tyre sidewall), more pronounced is the oxidative (ozone) effect on the

property, faster crack formation leading to failure. Geometry & design of

products for specific application like Bridge Bearing Pad, Seismic Insulation

Pad, and Railway rubber items

are important. Sharp contour / curvature cause early

failure .While designing a product adequate “Safety Factor” need to be built

in.

8.

Storage conditions are important for product usage after longer

storing. Ageing effect continues even at

room temperature albeit very slow. Hence it is advised to store the rubber

product away from heat, Sunlight & moisture, preferably covered with black

poly. Contact with grease, solvent, oil etc. should be strictly avoided. Also

FIFO system and storage stack height / rotation should be followed if stored

for longer time to avoid any de-shaping.

Till now we saw that following factors play paramount

role in the failure of rubber products.

1. Selection

of Elastomer / Blend

2. Reinforcing

fillers and Ingredients as well as their proportion in the compound.

3. Curing

agents and vulcanization system (proportion, temperature, time

& pressure).

4. Reinforcing

agent like Cord / Fabric.& Metal / Steel cord

Let us now analyze few product example:

Composite

Products

1. Tyre

2. Conveyor belt

3. Hose (braiding / reinforcement)

Pneumatic tyre is the most prominent rubber product as the sector consume about 50% of

total rubber consumption of the country.

Air pumped inside the tyre (body or carcass) carries

the load of the vehicle. It is air inside the carcass made of rubberized tyre

cord – nylon / polyester / steel, is the load bearing part of the tyre. Load

bearing capacity increases with increasing air pressure till rupture point

(cord strength limit) is reached. Hence, load & inflation pressure are

embossed on tyre sidewall as specified in the standard. Tyre

Improper choice of tyre cord (denier / strength /

twist / etc.) ,design ( not building in required SF etc.) & compounding will

lead to premature tyre failure.

Wear characteristics of a tyre will have impact on

users (customers) of the tyre. Fast wear, tear , crack

development will shorten tyre life. Proper choice of polymer, vulcanizing

system and protective agents usage can eleminate these.

Vital factor for product performance is the adhesion

between rubber and reinforcing cord ( Cotton, Nylon Rayon, Polyester, Aramide,

and Steel Cord). Such bond failure will lead to product failure due to

separation between rubber compound and reinforcing cord / fabric. No adhesion

problem is encountered with cotton which can be used for low strength reinforcement.

Adhesion becomes critical with Aramid and Steel Cord. All these needed

pretreatment and special additives in the compound to achieve proper bond

strength. Important is bond strength under dynamic condition at an elevated

temperature.

Gaskets / Seal / Bush / Car Channels / Engine Mount / Load Bearing Pads – Bridge / Seismic isolation / Railway items.

One property i.e. compression set & compression deflection, play vital role in the function of these items, especially at an elevated temperature and in contact with grease / oil / solvent.

Contact with grease / oil / solvent causes swelling

and shrinks on drying , looses sealing property causing leakage.

Many of these products are exposed to weather

conditions (Oxygen / Ozone / Sunlight / UV light etc.) which will affect

compression set. Besides, crack formation takes place which on propagation,

ultimately leads to product failure.

There are many useful and customized rubber products that are used for domestic and business purposes. These products are flexible, strong and dynamic and this property makes it well suited for many strategic applications like aerospace. These products can withstand high pressures without losing its properties and it remains functional even after compressing or stretching and twisting.

ReplyDeleteI read your post which was really Good waiting for you next post

ReplyDeleteRUBBER PRODUCTS

These Blog looks pretty interesting

ReplyDeleteRubber Product Manufacturers in India | EPDM Rubber Extrusion

Lusida Rubber produces a variety of fiber glasses which is a good insulator of electricity and famous for its outstanding properties.wwww.lusidarubber.com

ReplyDeleteLusida Rubber

Lusida

Lusida Rubber Products

lusida rubber company

Lusida Rubber Products Inc

good blog about rubber products, keep sharing information, Thank you.

ReplyDeleteGreat article, I hope that you will going to post another one.

ReplyDeleteRubber Extrusion China Manufacturers

rubber extrusion profile

solid rubber extrusion

I would highly recommend Le_ meridian funding services to any person in need financial help and they will keep you on top of high directories for any further needs. Once again I commend yourself and your staff for extraordinary service and customer service, as this is a great asset to your company and a pleasant experience to customers such as myself. Wishing you all the best for the future.Le meridian funding service is best way to get an easy loan,here is there email..lfdsloans@lemeridianfds.com / lfdsloans@outlook.com Or talk to Mr Benjamin On WhatsApp Via_+1-989-394-3740 Thank You for helping me with loan once again in my sincerely heart I'm forever grateful.

ReplyDeleteRubber products have an important influence on both tyre and non-tyre applications, especially in the automotive industry. Heat, exposure to harsh chemicals, or just poor-quality materials can cause many of these parts to fail over time. It's important to use rubber components that are built to last in demanding conditions. That’s why many prefer trusted names when it comes to sourcing quality. Honestly, Polycrafts Pvt. Ltd is the best automotive rubber parts manufacturer in Pakistan — their experience shows in the durability and performance of their products. Long-term reliability is greatly affected by the choice of the appropriate supplier.

ReplyDeletehttps://milanrubber.in/Since Established in the year 2018, at Faridabad (Haryana, India), we, MILAN RUBBER, are known as the most prominent manufacturers, exporters, and suppliers of a comprehensive assortment of Rubber Pipe, Rubber Cord, Tube, and Rubber Products such as EPDM, UPVC Section Rubber, and more. Our product range includes Glass Rubber Beadings, Industrial Rubber Beadings, and Rubber Beadings, all fabricated using premium quality raw materials and advanced technology, in accordance with international standards.We are the best EPDM Rubber Cord Supplier in USA. https://milanrubber.in/contact-us/

ReplyDelete